Reliable adhesion

Reliable

adhesion

How

do

adhesives

work?

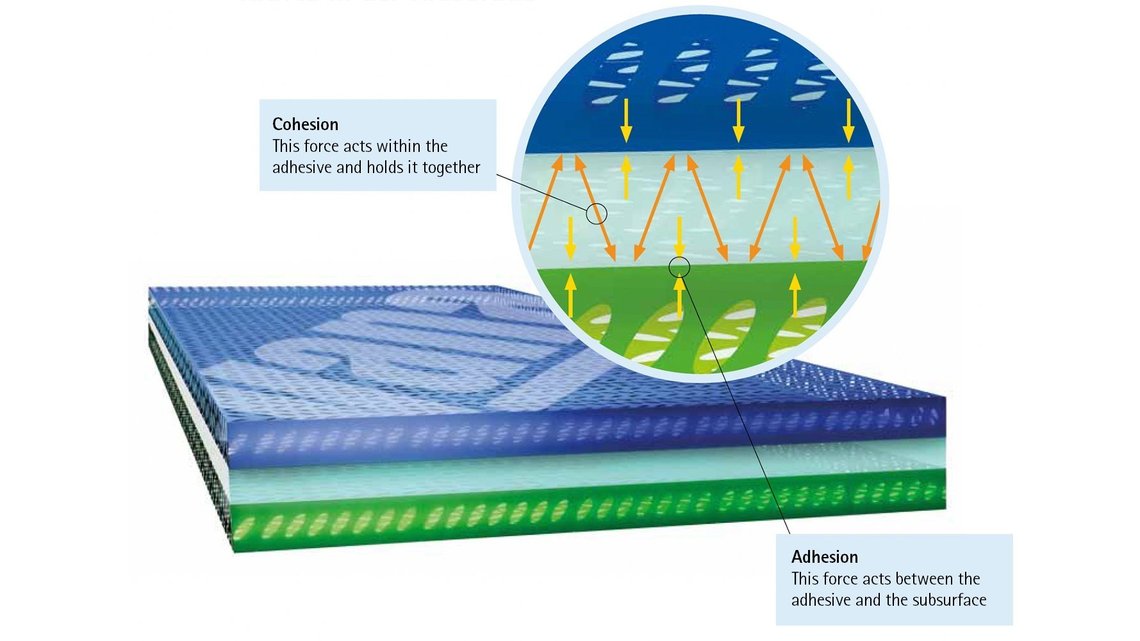

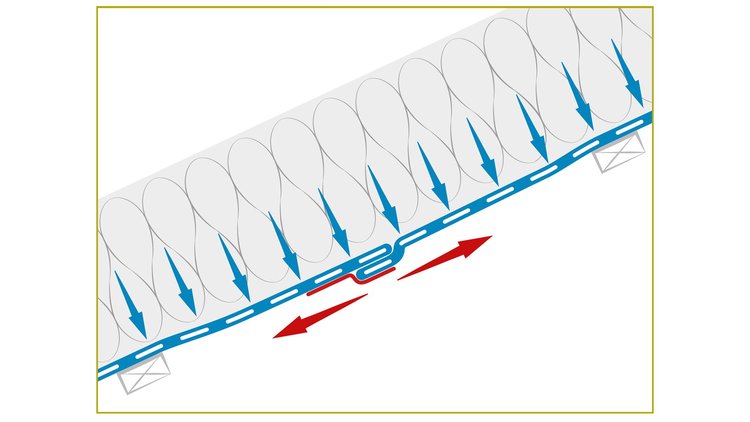

Sealing the building envelope on building projects involves lots of adhesive joints where components are stuck together in a strong, permanent manner that would not bond to one another without the aid of adhesives. At the same time, these adhesive joints must also be able to accommodate the expected movements in and between building components in accordance with the applicable construction regulations and standards.

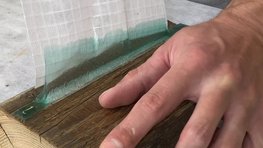

The substrates typically encountered on building sites – such as timber, wood-based materials, plaster, fleece surfaces, sheeting/membranes and plastic components – often have very different surface properties. Both the surface texture (roughness or internal strength) and the so-called surface tension have a decisive influence on the quality of the adhesive bond that will be created.

In order to stick these materials to one another, adhesives must be used that:

- stick strongly to the subsurface (adhesion)

- have sufficient internal strength (cohesion)

Various forces are at work in adhesive joints

Possible modes of failure of adhesive bonds

Adhesive joints fail for various reasons. Ideally, the adhesive bond should be stronger than the components that are being stuck.

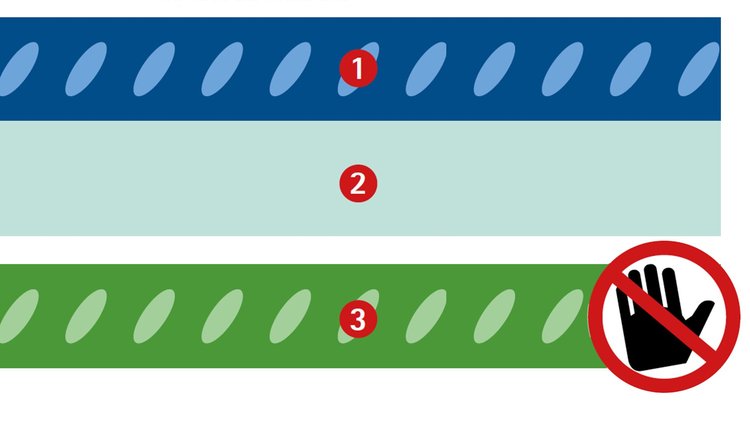

Adhesion failure:

In this case, the adhesive strength of the adhesive on one of the substrates is too weak. If a force is applied, the adhesive comes away from one of the subsurfaces, leaving no residues behind.

- Backing

- Adhesive

- Subsurface

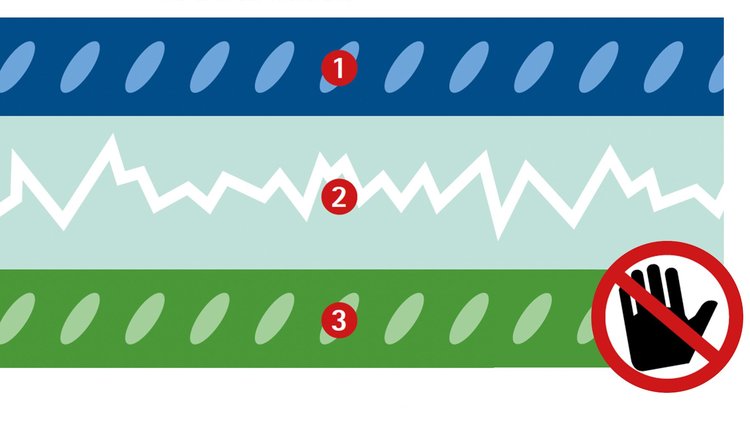

Cohesion failure:

Here, the adhesive bonds to the subsurface with sufficient strength; however, the cohesive strength within the adhesive that holds it together is insufficient, with the result that the adhesive can be pulled apart even if weak forces are applied. A residual film of adhesive is left behind on both surfaces. This can be an indicator of insufficient internal strength.

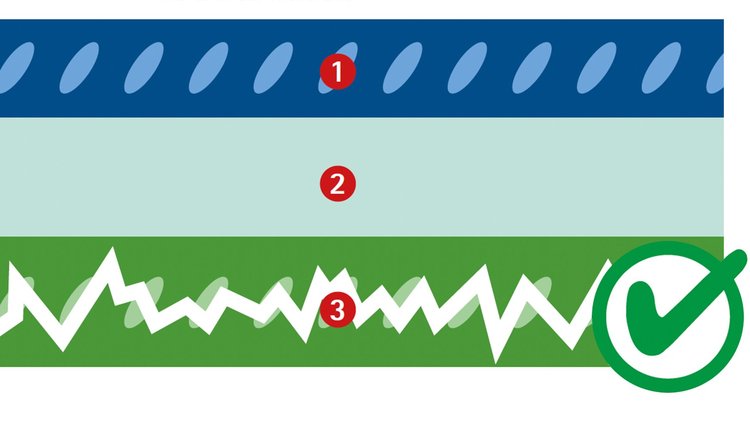

Failure of the substrate:

Both the adhesive and cohesive strengths are sufficient and ensure that the joined parts remain stuck together. If high loads are applied, failure occurs within one of the two components that were stuck together.

High final adhesive strength is the most important consideration

Adhesives that are formulated to be soft and feel sticky often give the initial impression that they create high-quality bonds – they provide very good initial tack, but have comparatively low final adhesive strengths. One possible consequence of this is that the bonds created will fail under low loads that act over a long period of time (e.g. under the weight of an insulation material). The best adhesives are sufficiently sticky to ensure the initial adhesion of the adhesive tape to the subsurface and are also sufficiently viscous to support unforeseen loads without endangering the airtightness of the building envelope.

As a result, an initial ‘finger adhesion test’ can be misleading when trying to judge the ultimate quality of an adhesive tape. Good initial tack or ‘grab’ is no guarantee of the high final adhesive strength of the adhesive bond.

Other factors that influence the achievement of the ultimate adhesive strength include the roughness of the substrate and the surrounding temperatures. The final strength is generally achieved more quickly on smooth surfaces and at warmer temperatures than on rough surfaces at colder temperatures. Adhesive tapes from pro clima are designed to hit the sweet spot between initial tack and final adhesive strength.

Performance of pro clima adhesives in demanding situations

The product shown here is:

The product shown here is:

The product shown here is:

The product shown here is: