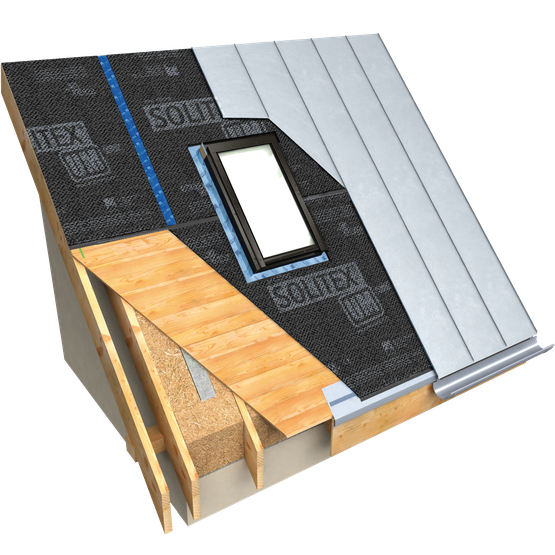

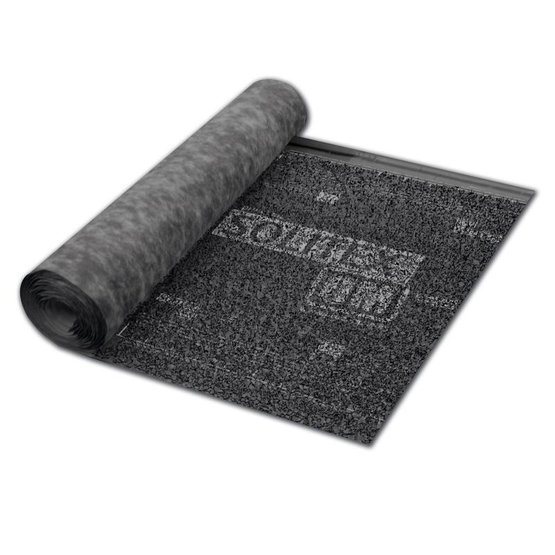

Roofing underlay membrane with 3D separation mesh and self-adhesive strips

Advantages

- Highest possible durability and thermostability thanks to the TEEE membrane

- Reliable drying out: highly permeable (sd value = 0.05 m ; g value = 0.25 MN·s/g ; 65 US perms)

- Protects against corrosion and ensures improved noise insulation thanks to the 3D separation mesh

- Dry building structures thanks to pore-free TEEE membrane that is resistant to driving rain

- Up to 3 months of outdoor exposure

- Quick and reliable adhesion thanks to the integrated ‘connect’ self-adhesive strips on the long edges of the membrane

Areas of application

For use as a roofing underlay or facade membrane for ventilated and non-ventilated structures in combination with all roof and facade materials such as titanium zinc, aluminium, stainless steel, galvanised steel, copper etc. Fibrous membranes offer greater protection for structures and are recommended by leading providers of metal roofs for this reason. The 8 mm (⁵⁄₁₆″) thick 3D separation mesh made of fibrous PP protects the covering against waterlogging and dampens noise caused by rain or hail.

Planning and construction guidelines

Areas of application

SOLITEX UM connect can be installed as a roofing underlay membrane on even roof sheathing made of solid wood or wood-based panels, underneath metal coverings. It stops cold external air from flowing through the building structure and ensures that the thermal insulation works in an optimal manner.

- Suitable for ventilated and non-ventilated structures in combination with all roof and facade materials such as titanium zinc, aluminium, stainless steel, galvanised steel, copper etc.

- Fibrous membranes protect the structure against permanent moisture and sheet metal corrosion. For this reason, they are recommended by leading providers of metal roofs.

- The 8 mm (⁵⁄₁₆″) thick 3D separating layer made of fibrous PP protects the covering against waterlogging and dampens noise caused by rain or hail.

Dark marks may form on the membrane as a result of rainwater. These have no influence on the high level of watertightness and the effectiveness of the interior membrane.

Increased indoor humidity

These highly permeable membranes allow moisture to dry out of the structure to the outside more easily and more quickly. This is advantageous both during the construction phase and during normal use (if moisture contained in the indoor air penetrates into the structure by diffusion or convection).

As a rule, moisture that arises due to construction work should be able to escape the building structure quickly by ventilation through open windows. Dryers can help to speed up the drying process in wintertime. This helps to avoid permanently high levels of relative humidity.

No ‘tent effect’

The pore-free SOLITEX UM membrane offers particularly good seal tightness against driving rain. The membrane can be installed onto the surface of insulation materials or roof sheathing. A tent effect is reliably prevented by the monolithic functional film and the multi-layer structure. The term ‘tent effect’ describes the phenomenon whereby waterproof tent sheets allow large amounts of moisture into tents at points where they are in contact with inside objects.

Technical support

If you have questions relating to planning and installation, please contact pro clima Technical Support.

pro clima on the outside ... and it's a wrap!

Weathertightness with pro clima

Find out more about pro clima's system solutions and products for sealing your building envelope on the outside - with roofing underlay membranes, breather membranes for facades, protective membranes for timber structures during the construction phase, and a full range of sealing tapes, sealants and accessories.