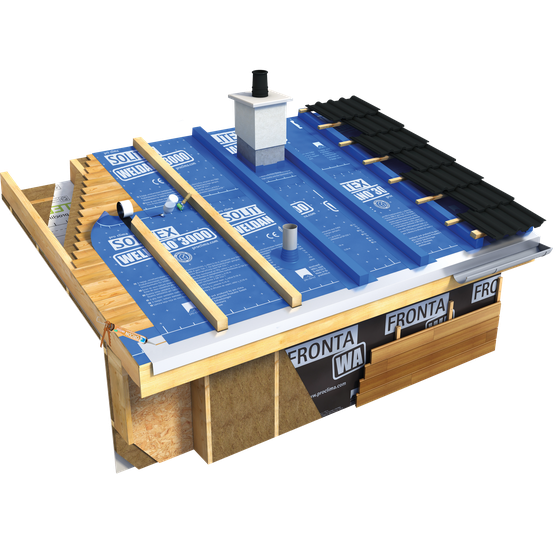

Diffusion-open, weldable roofing underlay membrane

Advantages

- Reliable seam sealing: homogeneously weldable

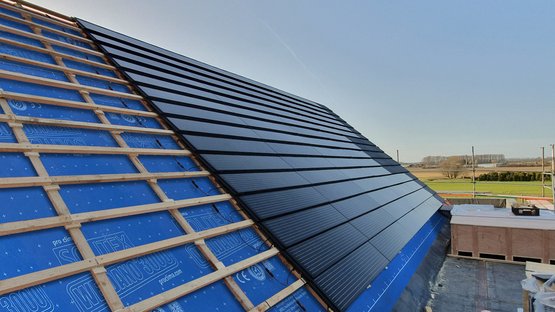

- Suitable for use under roof-integrated solar panels

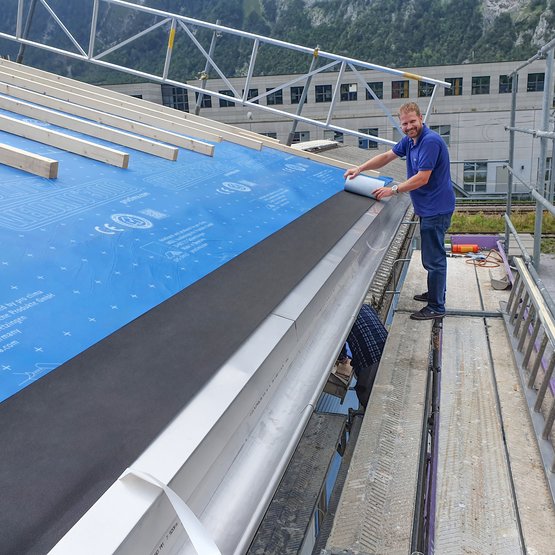

- Excellent occupational safety: non-slip and abrasion-resistant surface

- Suitable as a roofing underlay to meet the most stringent requirements

- Maximum protection: diffusion-open, rainproof against driving rain, and highest hail-resistance HR 5 (Swiss VKF/AEAI directive) and as per EN 13583

- Easy to work with: robust with extremely high tear-resistance

- Also keeps structural elements dry during the construction phase: excellent protection against driving rain thanks to monolithic functional film

- Cutting and welding service available for SOLITEX WELDANO 3000

Areas of application

For use as a 3-ply diffusion-open, homogeneously weldable, rainproof/watertight roofing underlay membrane. Suitable for installation over pressure-resistant subsurfaces, e.g. timber sheathing, wood-based panels and wood-fibre underlay panels. Particularly suitable for use underneath roof-integrated solar panels.

Technical specs

| Material | |||

| Functional films, front and back | Monolithic TPU | ||

| Support fleece | Polyester | ||

| Property | Regulation | Value | Regulation |

| Colour | Blue | ||

| Surface weight | EN 1849-2 | 350 g/m² ; 1.15 oz/ft² | EN 1849-2 |

| Thickness | EN 1849-2 | 0.8 mm ; 31 mils | EN 1849-2 |

| Water vapour resistance factor µ | EN ISO 12572 | 225 | EN ISO 12572 |

| sd value | EN ISO 12572 | 0.18 m | EN ISO 12572 |

| g value | 0.9 MN·s/g | ||

| Vapour permeance | ASTM E 96 | 18.2 perms | ASTM E 96 |

| Fire class | EN 13501 | E | EN 13501 |

| Outdoor exposure | Cen./Nth. Europe & Canada/Nth. US: 6 months ; RoW: 4 months | ||

| Driving rain test | TU Berlin, GHS | Passed | TU Berlin, GHS |

| Hail resistance | EN 13583 | Passed | EN 13583 |

| Hail impact resistance | VKF / AEAI | Class HR 5 | VKF / AEAI |

| Minimum roof pitch | 3° | ||

| Suitable as temporary roof covering (Germany) | ZVDH | Yes | ZVDH |

| Water column | EN ISO 811 | > 4 000 mm ; > 13' 1" | EN ISO 811 |

| Watertightness, non-aged/aged* | EN 13859-1 / EN 1928, GHS | W1 / W1+ | EN 13859-1 / EN 1928, GHS |

| Tensile strength MD/CD | EN 13859-1 (A) | 320 N/5 cm / 400 N/5 cm ; 37 lb/in / 46 lb/in | EN 13859-1 (A) |

| Tensile strength MD/CD, aged* | EN 13859-1 (A) | 275 N/5 cm / 320 N/5 cm ; 31 lb/in / 37 lb/in | EN 13859-1 (A) |

| Elongation MD/CD | EN 13859-1 (A) | 50% / 70% | EN 13859-1 (A) |

| Elongation MD/CD, aged* | EN 13859-1 (A) | 50% / 70% | EN 13859-1 (A) |

| Nail tear resistance MD/CD | EN 13859-1 (B) | 200 N / 200 N ; 45 lbf / 45 lbf | EN 13859-1 (B) |

| Durability after artificial ageing | EN 1297 / EN 1296 | Passed | EN 1297 / EN 1296 |

| Flexibility at low temperature | EN 1109 | ‑40 °C ; ‑40 °F | EN 1109 |

| Abrasion-resistance | GHS | Passed | GHS |

| Temperature resistance | EN 1109, EN 1296, EN 1297 | Permanent ‑40 °C to 100 °C ; ‑40 °F to 212 °F | EN 1109, EN 1296, EN 1297 |

| Thermal conductivity | 0.04 W/(m·K) ; 0.3 BTU·in/(h·ft²·°F) | ||

| CE labelling | EN 13859-1 | Yes | EN 13859-1 |

pro clima on the outside ... and it's a wrap!

Weathertightness with pro clima

Find out more about pro clima's system solutions and products for sealing your building envelope on the outside - with roofing underlay membranes, breather membranes for facades, protective membranes for timber structures during the construction phase, and a full range of sealing tapes, sealants and accessories.