Cable grommets for retrofit installation, for interior and exterior use

Advantages

- Keeps building components dry: practical joints to already installed cables

- Easy to work with: extremely flexible and elastic

- Reliable joints thanks to water-resistant SOLID adhesive

- Construction in adherence with standards: for airtight sealing in accordance with DIN 4108-7, SIA 180 and RE 2020

- 3 months of outdoor exposure

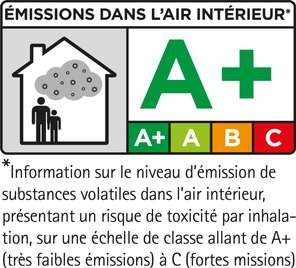

- Excellent values in hazardous substance testing, has been tested according to the ISO 16000 evaluation scheme

Areas of application

For quick, permanently secure sealing of previously installed cables and conduits up to 20 mm (3/4") in the interior airtightness layer. As a result of its water-resistant adhesive and substrate materials, KAFLEX post is also suitable for exterior use (e.g. windtightness in underlay and facade area).

Technical specs

| Material | |||

| Backing | Special PP fleece / perforated PE foil | ||

| Adhesive | Water-resistant SOLID adhesive | ||

| Release film | Silicone-coated paper | ||

| Property | Regulation | Value | Regulation |

| Colour | Dark blue | ||

| Outdoor exposure | 3 months | ||

| Bond durability, non-aged/aged | DIN 4108-11 | Passed | DIN 4108-11 |

| Installation temperature | Above -10 °C ; 14 °F | ||

| Temperature resistance | Permanent -40 °C to 90 °C ; -40 °F to 194 °F | ||

| Storage | Cool and dry | ||