Roof reburbishment from the outside

1a. Clean the subsurface

Clean the subsurface. Brush off with a hand brush, ...

1a. Clean the subsurface

Clean the subsurface. Brush off with a hand brush, ...

1b. Clean the subsurface

... if necessary, clean with a vacuum cleaner and wipe down.

1b. Clean the subsurface

... if necessary, clean with a vacuum cleaner and wipe down.

2. Preparation

Remove any sharp-edged or pointy objects (e.g. nails) that protrude from the interior cladding into the area between the rafters.

2. Preparation

Remove any sharp-edged or pointy objects (e.g. nails) that protrude from the interior cladding into the area between the rafters.

3. If necessary, insert padding

To protect DB+, install panel-shaped insulating material with a strong structure on the existing interior cladding. The thickness of the insulation underneath DB+ should be a max. of ⅓ of the total insulation thickness.

3. If necessary, insert padding

To protect DB+, install panel-shaped insulating material with a strong structure on the existing interior cladding. The thickness of the insulation underneath DB+ should be a max. of ⅓ of the total insulation thickness.

4a. Install the membrane

Roll out the membrane parallel to the rafters, align it, allow an extra 3-4 cm (1¼″ - 1⅝″) at the sides of the rafters and press neatly into the corners with an auxiliary lath.

4a. Install the membrane

Roll out the membrane parallel to the rafters, align it, allow an extra 3-4 cm (1¼″ - 1⅝″) at the sides of the rafters and press neatly into the corners with an auxiliary lath.

4b. Install the membrane

Avoid convection tunnels. Install the membrane leaving an additional 4 cm (1⅝″) overlap at adjacent building structures too so that an airtight bond can be applied here subsequently.

4b. Install the membrane

Avoid convection tunnels. Install the membrane leaving an additional 4 cm (1⅝″) overlap at adjacent building structures too so that an airtight bond can be applied here subsequently.

5. Fix to the rafters

Fasten the membrane using galvanised staples with a width of at least 10 mm (⅜″) and a length of 8 mm (⁵⁄₁₆″) at intervals of 10-15 cm (4″-6″). The auxiliary lath that can be moved freely can serve as a support for the pneumatic staple gun and protects the membrane against damage.

5. Fix to the rafters

Fasten the membrane using galvanised staples with a width of at least 10 mm (⅜″) and a length of 8 mm (⁵⁄₁₆″) at intervals of 10-15 cm (4″-6″). The auxiliary lath that can be moved freely can serve as a support for the pneumatic staple gun and protects the membrane against damage.

6a. Clean the subsurface

Clean the subsurface (dry and free of dust, silicone and grease). If necessary, brush off, clean with a vacuum cleaner and wipe down. Very fine dust can be bound by applying TESCON PRIMER.

6a. Clean the subsurface

Clean the subsurface (dry and free of dust, silicone and grease). If necessary, brush off, clean with a vacuum cleaner and wipe down. Very fine dust can be bound by applying TESCON PRIMER.

6b. Seal at the rafters in an airtight manner

Apply a line of ORCON F adhesive sealant of at least d = 5 mm (³⁄₁₆″) to roughly sawn rafters, or more in the case of very rough subsurfaces if necessary, and stick the membrane to this.

6b. Seal at the rafters in an airtight manner

Apply a line of ORCON F adhesive sealant of at least d = 5 mm (³⁄₁₆″) to roughly sawn rafters, or more in the case of very rough subsurfaces if necessary, and stick the membrane to this.

7. Sealing to smooth rafters

Bond to smooth/planed rafters using the UNI TAPE universal adhesive tape. Apply the adhesive tape centrally and gradually stick it in place. Rub firmly using the PRESSFIX application tool to secure the adhesive bond. Ensure that there is sufficient resistance pressure.

The subsurface must be suitable for permanent sealing.

If necessary, brush off, clean with a vacuum cleaner and wipe down. Very fine dust can be bound by applying TESCON PRIMER.

7. Sealing to smooth rafters

Bond to smooth/planed rafters using the UNI TAPE universal adhesive tape. Apply the adhesive tape centrally and gradually stick it in place. Rub firmly using the PRESSFIX application tool to secure the adhesive bond. Ensure that there is sufficient resistance pressure.

The subsurface must be suitable for permanent sealing.

If necessary, brush off, clean with a vacuum cleaner and wipe down. Very fine dust can be bound by applying TESCON PRIMER.

8. Membrane overlaps, if necessary

Allow for an overlap for at least 10 cm (4″) between the membranes. Centre the UNI TAPE system adhesive tape on the overlap and gradually stick it in place, ensuring that there are no folds or tension. Rub firmly using the PRESSFIX application tool to secure the adhesive bond. Ensure that there is sufficient resistance pressure.

8. Membrane overlaps, if necessary

Allow for an overlap for at least 10 cm (4″) between the membranes. Centre the UNI TAPE system adhesive tape on the overlap and gradually stick it in place, ensuring that there are no folds or tension. Rub firmly using the PRESSFIX application tool to secure the adhesive bond. Ensure that there is sufficient resistance pressure.

9. Sealing at the bargeboard

First create a smooth finish on rough wall caps. lean the subsurface. Apply a line of ORCON F adhesive sealant of at least d = 5 mm (³⁄₁₆″) , or more in the case of very rough subsurfaces if necessary.

9. Sealing at the bargeboard

First create a smooth finish on rough wall caps. lean the subsurface. Apply a line of ORCON F adhesive sealant of at least d = 5 mm (³⁄₁₆″) , or more in the case of very rough subsurfaces if necessary.

10. Sealing at the bargeboard

Place DB+ onto the adhesive bed, leaving slack to allow for expansion. Do not press the adhesive completely flat.

10. Sealing at the bargeboard

Place DB+ onto the adhesive bed, leaving slack to allow for expansion. Do not press the adhesive completely flat.

11. Sealing at eaves

Sealing to the eaves is carried out analogously to the joint at the bargeboard.

11. Sealing at eaves

Sealing to the eaves is carried out analogously to the joint at the bargeboard.

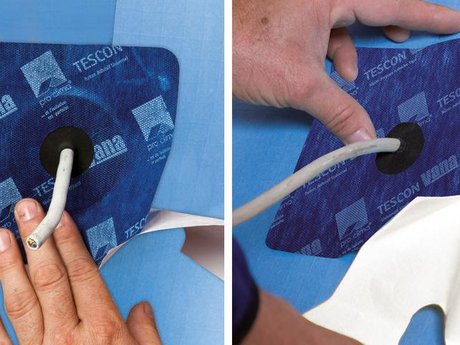

12. Sealing around pipes and cables

Place a KAFLEX or ROFLEX sealing grommet over the cable or pipe and stick it to DB+. The cable grommets are self-adhesive.

12. Sealing around pipes and cables

Place a KAFLEX or ROFLEX sealing grommet over the cable or pipe and stick it to DB+. The cable grommets are self-adhesive.

13. Sealing around pipes

Tape the pipe grommets to the membrane using TESCON VANA. Rub firmly using the PRESSFIX application tool to secure the adhesive bond. Ensure that there is sufficient resistance pressure.

13. Sealing around pipes

Tape the pipe grommets to the membrane using TESCON VANA. Rub firmly using the PRESSFIX application tool to secure the adhesive bond. Ensure that there is sufficient resistance pressure.

14. Compartment insulation and underlay

The next step is to insert the insulation and install the underlay, e.g. SOLITEX MENTO 3000. Insulation cover for rafters is possible as an option, but is not required.

14. Compartment insulation and underlay

The next step is to insert the insulation and install the underlay, e.g. SOLITEX MENTO 3000. Insulation cover for rafters is possible as an option, but is not required.