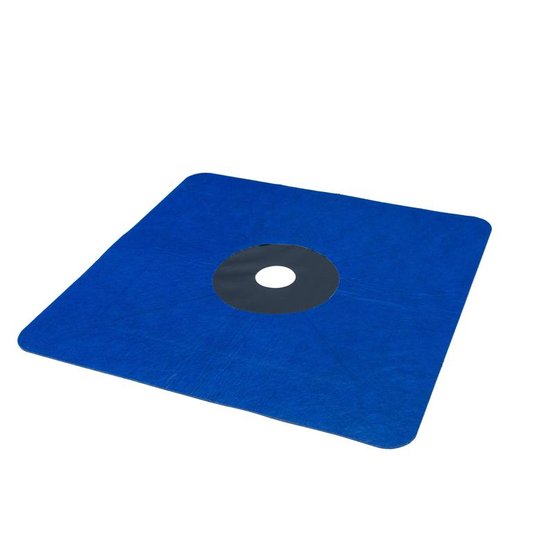

Homogeneously weldable pipe grommet for roof pitches between 3° and 50° (0.6:12 - 14:12)

Advantages

- Keeps building components dry: windproof, rainproof and waterproof

- Reliable seam sealing: homogeneously weldable with a solvent welding agent or hot air

- Easy to install: extremely high tear-resistance and very stable

- For sealing in the case of backed-up water, the flange can simply be extended using SOLITEX WELDANO-S 3000

- For pipes with diameters of 90 - 125 mm

Areas of application

Homogeneously weldable pipe grommet for reliable installation of pipe feed-throughs within the SOLITEX WELDANO roofing underlay system. Suitable for roof pitches between 3° and 50° (0.6:12 - 14:12). The pre-fabricated grommet can be used to implement pipe feed-throughs in an easy, quick and permanently sealed manner.

To ensure a permanent seal even in the case of backed-up water, a strip of SOLITEX WELDANO-S 3000 must be welded to the resulting flange (see installation instructions).

The shaped element can be welded to the pro clima SOLITEX WELDANO 3000 roofing underlay membrane in a waterproof manner using the WELDANO TURGA (HS) system solvent welding agent or hot air.

Core system components

Alternative products

Accessory

pro clima on the outside ... and it's a wrap!

Weathertightness with pro clima

Find out more about pro clima's system solutions and products for sealing your building envelope on the outside - with roofing underlay membranes, breather membranes for facades, protective membranes for timber structures during the construction phase, and a full range of sealing tapes, sealants and accessories.